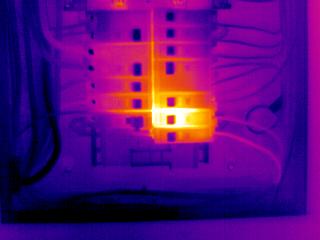

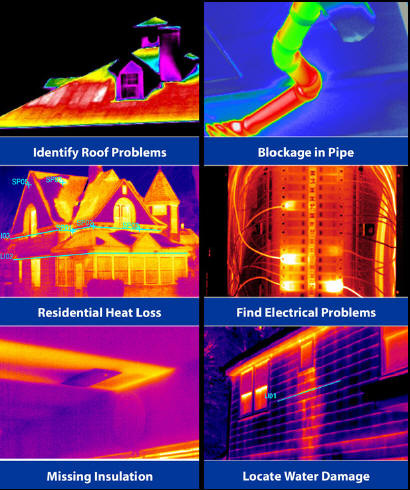

Thermal ImagingSeifert Electric is a certified thermal imaging contractor. Thermal imaging is a method of improving visibility of objects in a dark environment by detecting the objects' infrared radiation and creating an image based on that information. Seifert Electric uses thermal imaging to identify problems within electrical distribution systems, both while the trouble is present and in advance, through routine preventive maintenance. Thermal imaging is good for predictive maintenance and troubleshooting. With out thermal imaging camera we are able to find and detect future problems and then fix them before they cause any harm. Here's a brief explanation of how thermal imaging works: All objects emit infrared energy (heat) as a function of their temperature. The infrared energy emitted by an object is known as its heat signature. In general, the hotter an object is, the more radiation it emits. A thermal imager (also known as a thermal camera) is essentially a heat sensor that is capable of detecting tiny differences in temperature. The device collects the infrared radiation from objects in the scene and creates an electronic image based on information about the temperature differences. Because objects are rarely precisely the same temperature as other objects around them, a thermal camera can detect them and they will appear as distinct in a thermal image. Electrical systems are very important to facility operations. If an important electrical component or motor fails, operations are forced to shut down. The shut down may cause safety issues to arise, result in revenue lost, and cause other equipment to be damaged.  CommercialSome components that Seifert Electric will check are:

ResidentialThermal Imaging can also provide important information relating to inaccessible areas of a residential building. These problems may include:

|